Premier Aluminum Llc - Questions

Premier Aluminum Llc - Questions

Blog Article

Premier Aluminum Llc Fundamentals Explained

Table of ContentsThe Best Strategy To Use For Premier Aluminum LlcPremier Aluminum Llc for BeginnersGetting My Premier Aluminum Llc To WorkPremier Aluminum Llc Fundamentals Explained

(https://trello.com/w/premieraluminum/members)Generally, a purchaser's main responsibility was to discover professional and responsive suppliers. Sometimes, buyers presumed that any kind of provider willing to contractually satisfy the acquisition requirement was qualified. Making use of low expense and unqualified distributors can cause high quality concerns, and squandered time and cash in the long run. To aid you through the procedure, here are some things to take into consideration when picking the right steel spreading provider.

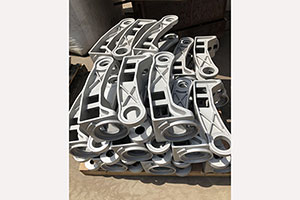

A firm that just makes use of the financial investment spreading procedure will certainly attempt to market you on why that process is best for your application (Foundry near me). However suppose utilizing the sand spreading process is best for you and your demands? Instead, search for a vendor that uses a series of casting processes so the very best choice for YOU is chosen

If working with a single resource for every one of your casting needs is necessary to you, the distributor requires to be diverse in its capacities. When incorporated with various other integrated capabilities, this can aid streamline and compress the supply base. When picking the appropriate spreading provider, careful factor to consider must be offered to quality, solution, and cost.

Not known Factual Statements About Premier Aluminum Llc

Purchasers progressively select spreading vendors who have machining capacities. This can prevent conflict if issues are discovered throughout machining. If a 3rd party is machining, it might result in "finger-pointing" concerning who is at mistake. Is it a spreading issue or a machining issue? If the spreading vendor discovers an issue throughout machining, the problem is resolved much faster with no disagreement over whose fault it is.

Trouble or no, integrated machining simplifies the supply chain and lowers dealing with time and delivery cost before the item makes it to the customer. What do you need from your spreading distributor? Are you trying to find a person to just deliver a metal element to your front door or do you require much more? For instance, if you do not have in-house metallurgy competence, verify that the distributor can offer assistance in selecting the appropriate alloy based upon your details application - Aluminum Casting.

Some factories are restricted or specialized. Make sure the supplier can satisfy all your material or alloy requirements to eliminate the need for several vendors.

Some Known Incorrect Statements About Premier Aluminum Llc

Study the supplier's site. Talk to a sales representative or service associate.

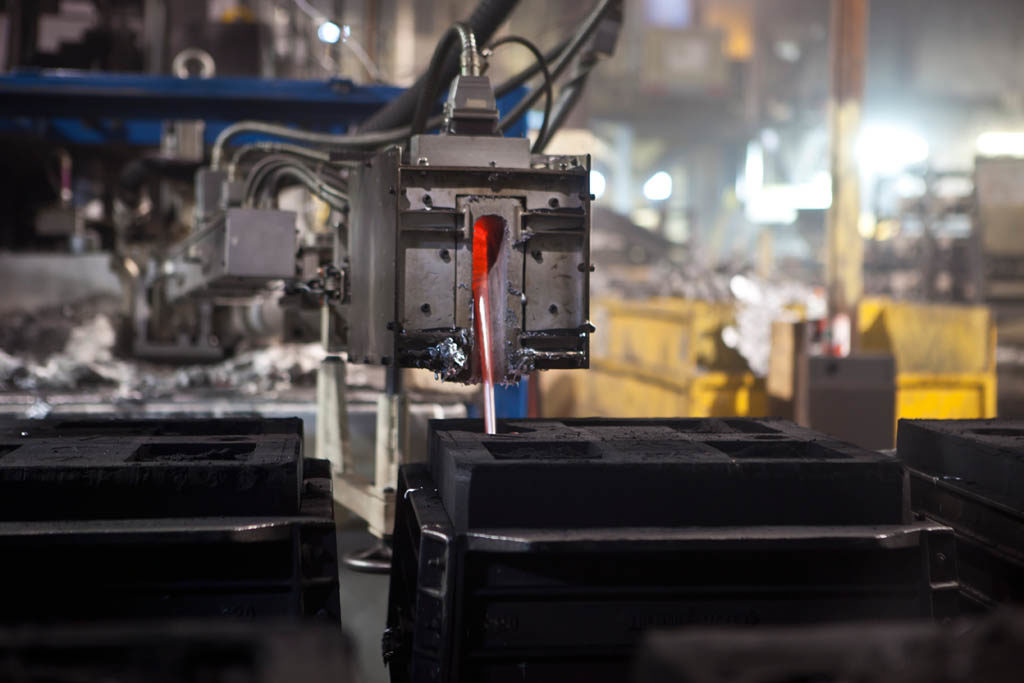

Light weight aluminum is also lightweight and has excellent corrosion resistance, making it ideal for applications where weight and longevity are essential variables. Furthermore, light weight aluminum casting is a cost-effective technique of production, as it requires less energy and sources than other techniques. Iron spreading, on the various other hand, includes putting liquified go to this site iron into a mold to produce a wanted form.

Our Premier Aluminum Llc Statements

Iron casting is also able to endure high temperatures, making it appropriate for use in applications such as engine parts and industrial machinery. Iron spreading can be extra pricey than light weight aluminum spreading due to the higher cost of raw materials and the power called for to melt the iron. When making a decision between aluminum spreading and iron casting, it is necessary to take into consideration the details demands of the application.

In final thought, both light weight aluminum spreading and iron casting have their very own special advantages and downsides. There are 3 sub-processes that fall under the category of die casting: gravity die casting (or permanent mold spreading), low-pressure die spreading and high-pressure die spreading. To get to the ended up product, there are 3 key alloys utilized as die spreading product to choose from: zinc, aluminum and magnesium. Report this page